- Home

- Product Center

- Conveyor Belts

- Mesh Belt for Furnace

Furnace Belting - AISI 310 Annealing Furnace Conveyer Belt, Sintering Belt, Brazing Belting for Conveyorised Furnace

Furnace Belt is a crucial component of a conveyor furnace system used for various industrial heat treatment processes. This mesh belt serves as the conveyor platform for transporting materials and products through the furnace, mainly for annealing, sintering, controlled heating, cooling, or other thermal processes.

Materials: Conveyor furnace mesh belts typically constructed from stainless steel alloys such as AISI-310, AISI 304.

Mesh Types: Varies mesh structures available, from fine mesh to coarse grid, allowing for proper airflow and heat distribution.

Major Applications:

Furace conveyor belt is used for processes as annealing, brazing, sintering, tempering, and heat treating various materials,

In industries including

- Metallurgy;

- Automotive;

- Electronics;

- More.

Conveyor Furnace Belting Mesh Products

Common specifications for furnace belting mesh: 2x6, 8x10, 10x15, 15x20, etc.

Customized products and services available.

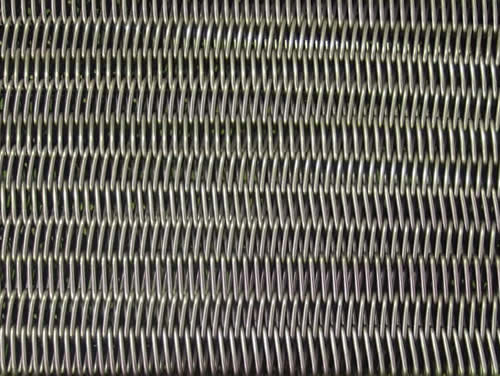

Stainless Steel Wire Mesh Conveyor Belt for Bright Annealing Furnace for Machinery Plants

Description:

Stainless Steel Wire Conveyer Belt (Meshed)

For Stainless Steel Tube Bright Annealing

Width 180 mm

Length 75000 mm

Cross Wire Diameter 3.5-4 mm

Winding Wire Diameter 3.5-4 mm

Spare from upto down: 35 mm

Spare from right to left : 12 mm

Max . Load 4-7 Kgs / m of belt

Material required: Heat Resistant Stainless Steel (AISI-310)

Max. Working Temperature 1150 °C

Design:

Conveyor furnace mesh belt in SS310 for annealing of SS tubes

Export to Karachi Port Pakistan Market

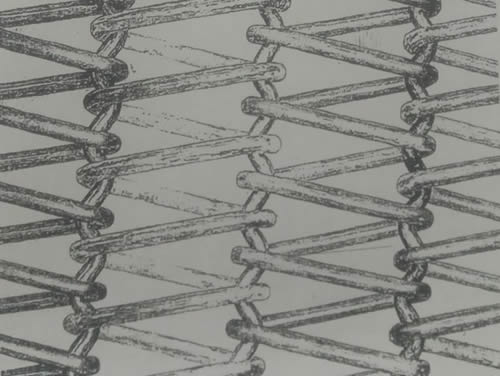

Mesh Conveyor Belt for Sintering Furnace

Description:

Continuous mesh belt for powder sintering furnace

Work condition:

The furnace works at two different temperature depending on type of powder that we need to sinter:

1) Powder 1 1120-1150 degree

2) Powder 2 750-850 degree

Mesh belt size: 42 m x 150 mm

Sintered powder put on graphite base and put on the belt

Weight: 150-160 kg transport

Exported to Italy market

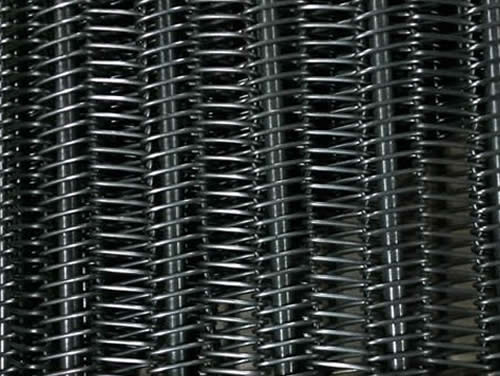

Brazing Belting for Conveyorised Furnace

Description:

Furnace replacement conveyor belt - Balanced Weave Spiral Mesh

Service temperature of furnace 1140 degree C.

Atmosphere of furnace: 15%H2 85%N2

Specification of the mesh belt as follows:

Material: SS310 Grade

Size: 350mm wide 23m Long

Type: Balance Weave Spiral Mesh

No. of Spiral across the width in 305mm - 62

No. of Spiral down the length 305mm - 18

Connecting (across )rod wire diameter - 3mm

Spiral wire diameter - 2.2mm

Spiral (link / belt ) height - 10mm

Belt edge - Non welded

Exported to Singapore

Stainless Steel Wire Mesh Products

- Ring Shaped Filter Disc

- Mesh Discs Twill Weave

- Plain Steel Mesh Filter Discs

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen