- Home

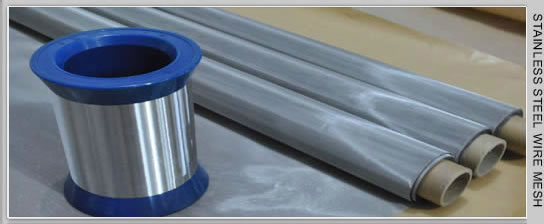

- Product Center Stainless Steel Knitted Wire Mesh

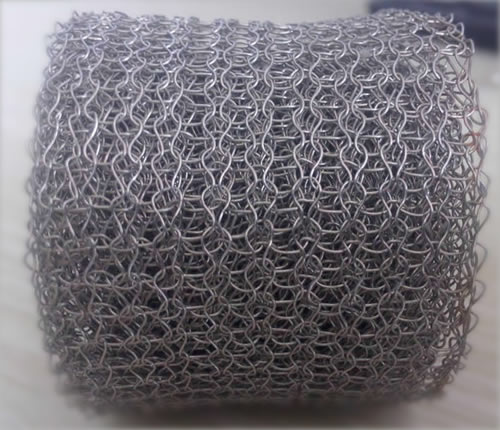

Stainless Steel Mesh, Knitted

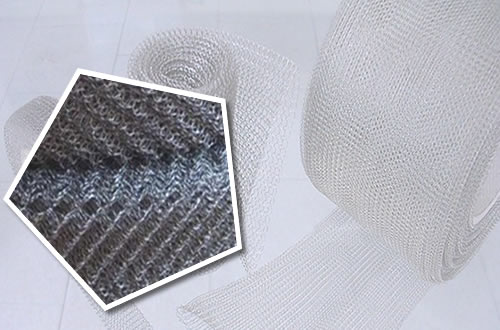

Hehua is a China supplier of knitted wire mesh made from stainless steel, monel, nickel and copper wire. Knitted Mesh is a wire cloth woven by a circular knitting process which produces a sleeve of continuous stocking of inter-linked wire loops.

Wire Diameters

Knitted Mesh Fabric is normally knitted form round or flat wires ranging in various diameters. When used as filter in large surface area cleaning and air-filtration, the wire diameter of knitted wire cloth affects flow, dirt holding capacity and pressure drop. In general, knitted mesh with large wire diameter allows for higher flow but provides lower dirt holding capacity. Also larger diameter wire is less expensive.

Density

Density refers to the mass of material per unit volume. A higher density filtration can be achieved for higher cost fine wire, lesser density at heavy wire. Proper density is critical for optimal performance of the knitted wire mesh sealing, gasket, filtration and separation applications.

Structure & Properties of Knitted Wire Mesh

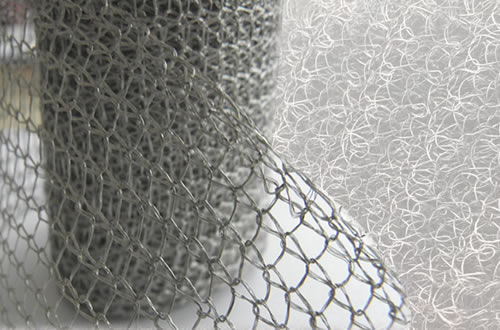

Knitted metal mesh has distinct advantages over other mesh materials. The loop structure gives knitted wire greater in plane springiness or two-dimensional flexibility. Knitted mesh can be crimped or compressed to alter characteristics for specific applications. Knitted wire loop acts as a small spring when subjected to tensile or compressive stress. If it's not distorted beyond its yield point, the material will resume its original shape when the stress is removed. Even the compressed form has a high degree of resiliency. Knitted metal also provides high mechanical damping characteristics and non-linear spring rates. Vibration and mechanical shock can be effectively controlled, hence the knitted metal can provide ample protection from dynamic overloads.

General Technical Information

Metal Materials Applied:

•Stainless steel AISI304, 316, 304L, 316L,

•Magnetic stainless steel 430, 410

•Nickel and Nickel Alloy

•Monel

•Copper and tinned copper clad steel

Wire diameter ranges: 0.12-0.45mm

Width: 10-600mm

Wire Shapes: Round wire, flat wire

Mesh Materials Applied

Monel Knitted Mesh is a nickel alloy offering good corrosion resistance and strength. A kind of nickel based wire cloth, containing minimum 63% Nickel and 28% Copper. Suitable for marine and chemical environments.

Tinned Copper Clad Steel Mesh has the best shielding performance of all wires used in knitted meshes, combining low contact resistance with a small degree of permeability. It is not suitable for highly abrasive applications where the TIN plating may wear away to expose the copper. The corrosion resistance of tinned copper clad steel knitted wire is suitable for most applications.

Aluminum Knitted Mesh is mechanically weak and will readily take a compression set and this combined with its readiness to form a non-conducting oxide.

Stainless Steel Mesh Knitted finds popular uses in auto parts and other engineering applications.

SS Knitted Mesh offers excellent property such as corrosion resistance, alkali and acid resistance, rust resistance and heat resistance.

304 Stainless Knitted Wire Mesh

Material: 304 Stainless steel

Type: Knitted Wire Mesh, 26 needles

Wire Diameter: .002", .0025"

Fabric width: 1"

SS 304 Wire Mesh, Knitted Type

Material : AISI 304 wire mesh

Type : Continuous knitted type, 6 meshes per linear inch

Wire diameter: 0.193mm / SWG36, 0.315mm / SWG30

Packing: 100mm width rolled into a cylinder of weight appx. 2.5 to 5kgs

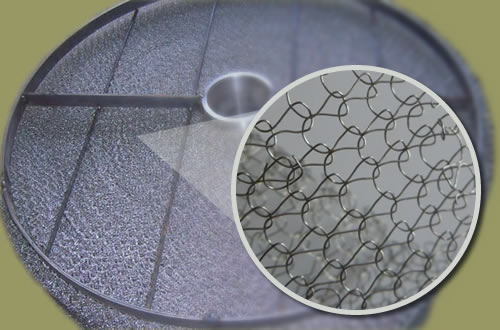

SS 304 Knitted Mesh Processing into Vane Type Demister Pads (W type), designed for Turkey, Thailand, India and Pakistan, mainly used for separating diameter greater than 3 ~ 5 micron droplets.

410 and 430 SS Knit Mesh is a kind of magnetic stainless steel mesh, used as main component of mesh demister and other separation engineering or electromagnetic wave shielding net.

Type 430ss Mesh Net, 011", 336N, 43" crimped, degreased, in rolls measuring 580 mm

Forms

Knitted wire fabrics can be processed into compressed, pleated or pad forms to allow liquid or gas flowing through.

Application:

Knitted wire mesh is made from all materials for processing of the following parts:

Filters Oil and Air Breather Elements;

Catalytic Converter Insulator Blanket Mesh;

Mufflers and Silencers;

Copper Mesh Oil-Bath Separators

Mist Elimination Pads;

Demister Filter;

Oil Filter Mesh Pad;

Cushion Blocking;

Automotive Filter Components;

Wire Mesh Breathers for Engine and Automobile Oil Filtration System;

Air Filters and Separators;

Auto Parts for Exhaust System;

EMI Shielding System Parts.

Industries Served:

Knitted Metal Nettings are widely used in gas-liquid separation device for chemical, petroleum, environmental protection, machinery, ships and other industries.

Nickel Alloy / Monel Mesh Mist Eliminator

Monel Mesh Blankets for Evaporators Parts, Type: Knitted mesh pleated, Mesh Material: Monel (Nickel Alloy 400- Copper alloy), structure: mesh fabrics assembled in multiple layer section, supported and sandwiched in monel, thickness: 6½ ( I50 mm ), Density 9 lb/ft

Micron 70-90% Compressed SS Mesh Knitted, used for auto parts exhaust system and EMI shielding system.

Stainless Steel Wire Mesh Products

- Ring Shaped Filter Disc

- Mesh Discs Twill Weave

- Plain Steel Mesh Filter Discs

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen