- Home

- Product Center Technical Parameters about SS Wire Mesh

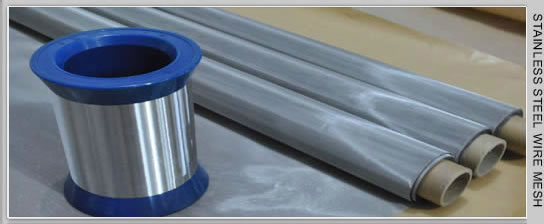

Stainless Steel Wire Mesh - Processing Condition and Main Parameters

In this page, we mainly introduce condition requirements for processing of stainless steel wire mesh, also major technical parameters including mesh, wire, roll size, aperture, weaving type, edge treatment and etc.

Stainless Steel Wire Mesh Processing Condition

Stainless Steel Wire Mesh: Wire Processing and Mesh Processing Conditions and Temperature Requirements

Stainless steel wire mesh is made of choice stainless steel wire drawn to specified wire diameter at a high temperature under specific conditions. The wire is then woven with the weaving looms into stainless steel wire mesh at dust-free and clean workshops of fixed temperatures.

Features of SS Wire Mesh: It has structural precision, uniform mesh, good filtration, abrasion resistance, high temperature resistance, acid resistance, corrosion resistance.

Uses:

1.For acid and alkali conditions screening and filtering.

2. Quarry screen in oil industry, filter screen in chemical fiber industry, acid washing mesh in electroplating industry.

3. Used in industry and construction for filtering sand, filtering liquid and gas.

Main Parameters for Stainless Steel Mesh:

1: Material:

Stainless steel wire, nickel wire, brass wire. Stainless steel wire is divided into: SUS302, 304,304 L, 316,316 L, etc.

2: Mesh / Mesh Counts

Number of openings per inch is called mesh. Mesh reflects thin or dense of the wire mesh. Generally the stainless steel wire mesh with more than 80 mesh is called fine mesh, less than 80 mesh is called coarse mesh.

3: Wire Diameter: Unit: mm or inch. Stainless steel weaving wire can be divided into warp wire and weft wire. Warp wire is also known as line wire. Weft wire is also known as cross wire or shute wire. For example; 80 × 80 × 0.12mm means: 80 mesh, wire diameter 0.12mm. It can also be written as: 80 × 80 × AWG40 × 1m × 30m. 80 is the mesh, wire diameter AWG40, roll width: 1m, length: 30m

4: Aperture / Mesh Size / Opening Size: unit: mm, inches.

5. Weaving Type applied for Stainless Steel Mesh:

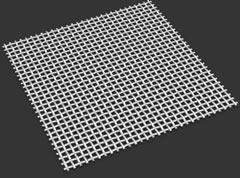

1: Plain Weave, Simplified as PW

Plain weave: Each warp wire passes across the top and bottom of each weft to form a 90 degree. The warp and weft wire applied have the same diameter.

2: Twill Weave, Simplified as TW

Twill weave: Each warp wire passes across in the top and bottom of each two weft wire, each weft wire passes across each two warp wire up and down.

3: Dutch Weave, Simplified as DW

Dense woven wire mesh made with the warp and weft wire of different wire diameters and different mesh numbers in warp and weft directions. It is characterized by less warp mesh and more weft mesh and thick warp wire and fine weft wire. The longitudinal direction is called the warp, the opposite is called the weft. Dense woven Dutch wire mesh is divided into Plain Dutch Weave and Twill Dutch Weave.

4: Dutch twill weave: Each warp wire crosses through every two weft wire above and below, while each weft wire crosses every two warp wire above and below.

5: Double Wire Dutch Weave: This weave type is similar to Dutch twill weave, but the weft wire is composed with doubled wire, tightly stacked against the warp wire. This wire cloth is used for micron filtering.

6: Five-Heddle Weaving: The warp and weft wire applied for this weaving type are not single wire. It is made with several separating wires. This weaving is to provide a more powerful solid stainless steel wire cloth on Twill weave basis.

6: Selvage / Edge Treatment is different for Stainless Steel Wire Mesh Woven with Shuttle Looms and Shuttless Looms:

Weaving Machine With Shuttle: Wire mesh under 20 mesh is commonly made with wrapped edges (Close Selvage, Round Ended).

Shuttleless Machine: Wire mesh under 20 mesh is made commonly with flash edge.

Shuttle loom and shuttleless looms differences: Shuttle loom drives the weft wire with shuttles, shuttleless looms works by pulling the weft wire with the sword.

7: SS Wire Mesh Roll Width Unit: meters, inches, feet.

8: Roll Length units: meters, inches, feet.

Common stainless steel mesh roll width and length: Roll width used: 3 ', 4', 5 ', 6' i.e.: 0.914m, 1.22m, 1.524m, 1.83m

Roll length: 100 '= 30.5m

9: Quantity: Square meter or square meter/roll.

10: Packing: Common packing includes paper tube inside, waterproof paper outside(Kraft) + plastic cloth+ woven bags + bubble pad (200 mesh or more optional).

Stainless Steel Wire Mesh Products

- Ring Shaped Filter Disc

- Mesh Discs Twill Weave

- Plain Steel Mesh Filter Discs

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen