- Home

- Product Center

- Steel Wire Products Pocket Spring Mattress Wire

Pocket Spring Mattress Wire

We supply good quality spring wire for pocket spring mattress production.

Differences between Pocket Spring and Bonnel Spring

Both pocket spring and bonnel spring are innerspring units for mattress springs, while bonnel spring is the most popular springs used for bed mattress production;

Pocket spring is individually wrapped coil system stitched into mattresses below a comfort layer of foam or other material, while bonnel spring is the traditional interconnected spring system;

Pocket springs offer added contour and pressure point relief, while bonnell springs render more air circulation and provide maximum comfort.

Pocket Spring Wire

Diameter: 1.20 to 2.10mm

For producing pocket spring mattresses

Flat Frame Wire

10 x 1,40mm

For production of flat frame spring pocket:

Packaging - 200 kg per coil, 4 coils per pallet.

Product: Scaleless Blue Oil Tempere fre Steel Mattress Frame Wire

Wire section: Flat

Size: 10.0x1.40MM

Width: +/- 0.20mm

Thickness: +/- 0.05mm

Mechanical features:

Tensile Strength 1300-1600 N/mm2

Hardness: C41-49

Width tollerance: +/-0.20 mm

Thickness tollerance: +/-0.05 mm

| C | Si | S | P | Mn |

| 0.30-0.60 | 0.10-0.35 | 0.035 | 0.035 | 0.50-0.70 |

Technical Data Sheet - How we control and check wire qualities

Sample investigation

Dimension: 1,40 x 10,00

cc: T. Wittmers, Dr. V. Blinov

3 sample segments: 10,00 x 1,40 x ~ 25,00

Investigations to be carried out:

- chemistry

-

surface hardness

-

core hardness

-

microstructure

-

edge condition

Product chemical analysis:

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Al |

| 0,347 | 0,194 | 0,5683 | 0,0087 | 0,0070 | 0,017 | 0,017 | 0,001 | 0,011 | 0,0019 |

| Ti | V | Nb | W | Co | B | Ca | Sn | Pb | Zn |

| 0,0003 | 0,002 | - | - | - | - | - | - | - | - |

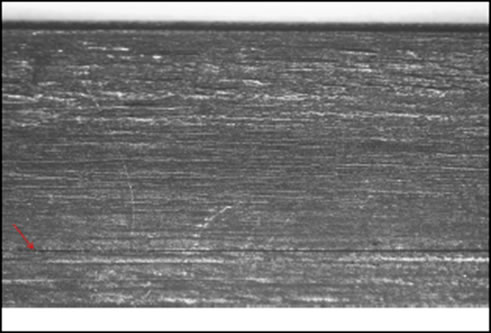

Fig. 1 Overview of belt surface

with marking of a surface defect

running in the middle in

longitudinal direction (one-sided

on all three samples)

The following is a cross-section

Surface hardness: 47HRC

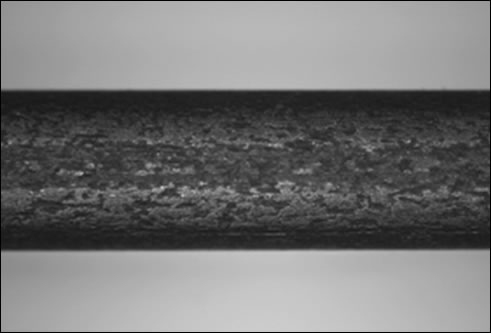

Fig.2 V iew of strip edge

Surface rough-porous

Origin: wire production

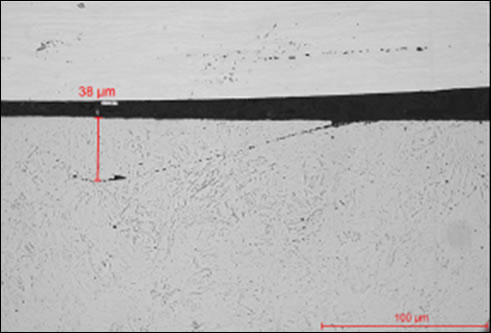

Fig.3

Cross-section

Failure area x500

Failure depth ca.38µm

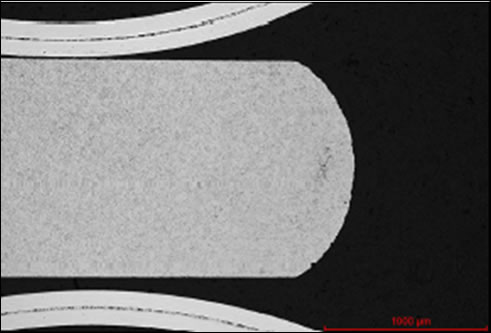

Fig.4

Cross-sectionx50

View of strip-edge across

Unetched

Surface slightly rough

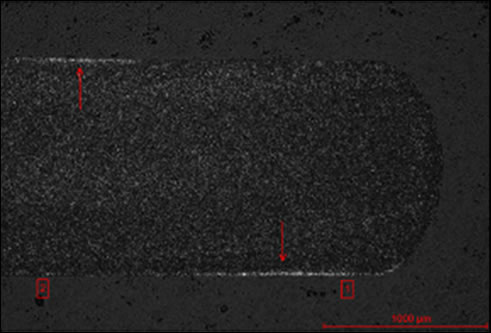

Fig.5

Cross section x50

Overview strip-edge

Etched

Partially decarburised

with marking of the following

image sections

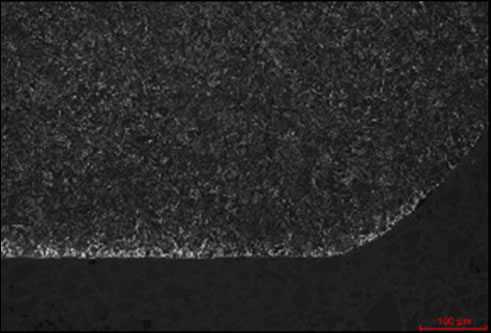

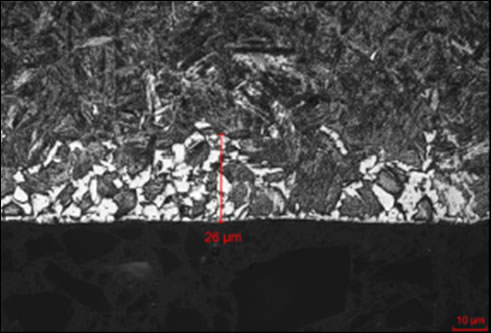

Fig.6

Image section 1 X200

Partially decarburised

Fig.7

Image position 1

Detail enlargement x1000

Decarburisation 26µm

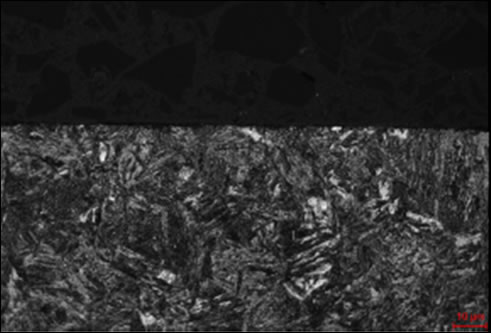

Abb.8

Image position 2

x 1000

No abnormalities

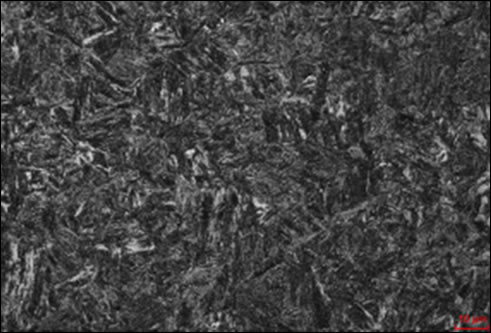

Fig.9

Core section x 1000

Core hardness: 490HV1

Stainless Steel Wire Mesh Products

- Ring Shaped Filter Disc

- Mesh Discs Twill Weave

- Plain Steel Mesh Filter Discs

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen